Tourbillon Mechanica Tri-Axial Crowdfunding

Created by

-

$ 85,503

raised

-

1642

pioneers

Campaign Closed: Tue, February 08, 2022 at 02:30 PM GMT

Mechanistic

Mechanistic

- Pledges (3)

- Add-ons (0)

-

$85,503.46

raised

-

1642

pioneers

Tiers

142 pioneers

USD 25.00

Tourbillon Mechanica - Tourbillon Escapement Mechanical Clock (Assembly guide pdf in description)

Summer sale is here till end of August! Use the code MECHA40 for 40% off applicable to the entire store!

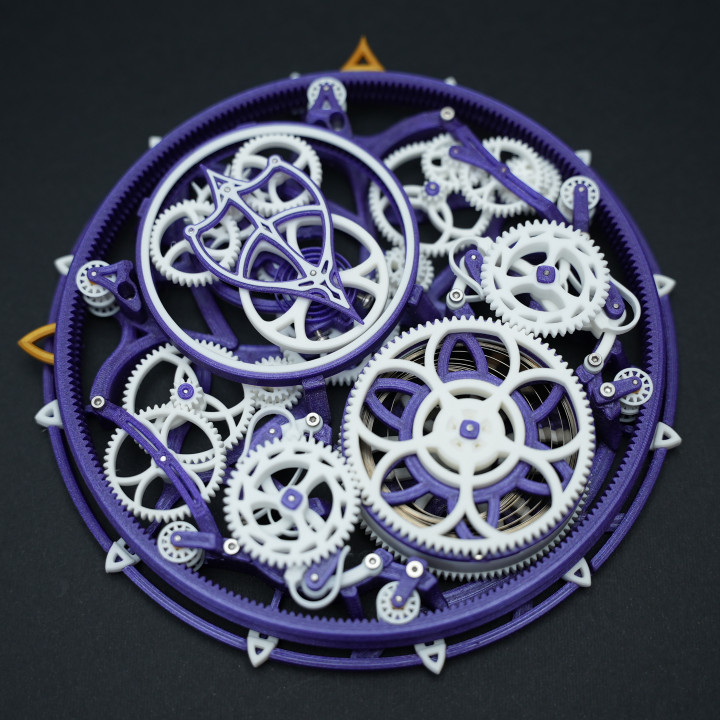

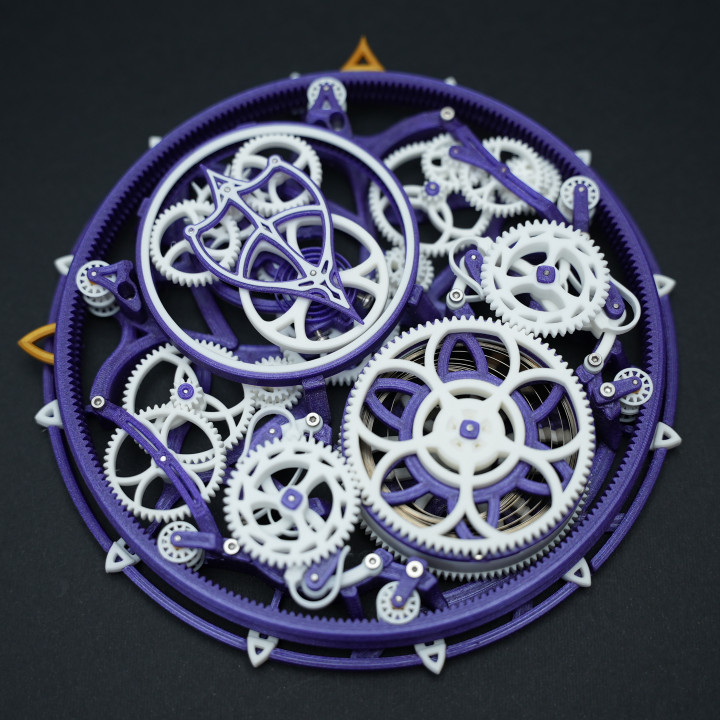

The Tourbillon Mechanica is an almost entirely 3D printed functional mechanical clock (except for metal pins and screws)

This skeletonized mechanical clock with a tourbillon escapement is designed to showcase a basic mechanical watch's mechanism. It has a unique hour and minute indicator that runs around the perimeter in order to showcase the entire mechanism.

Detailed assembly video guide: https://youtu.be/E9prY3ky6Bo

Detailed assembly guide, preparation and printing details: here

I received many requests on whether or not the Base (The largest single piece part) can be fitted onto some printers with slightly smaller rated build volume. There is a new split base and ring gear option that only requires a 160 x 110mm build area to print the entire model. The base and ring gear files can be downloaded for free as a fit check here.

Links to additional hardware that I used:

1.5mm OD Pins: Link

2.0mm OD Pins : Link

M2 Scews: Link

Sheet Spring Steel for mainspring : Link (Optional as I highly recommend using the 3D printed PETG spring)

Update Oct 09, 2021

Design Update:

- 10_Base_Split : Added split base option to reduce minimum printer bed size requirement significantly to 160 x 110mm

- 13_Ring_Gear_Split : Added split Ring gear option to reduce minimum printer bed size requirement

Assembly Guide Update:

- Page 3 : updated min print bed requirement from 220x220mm to 160x110mm

- Page 4-5 : added split base and ring gear assembly details

Update Dec 6, 2020

Added Step file of Base for those who wanted to try modifying it to fit smaller print beds. Step file can also be downloaded for free in the link above

Update Oct 27, 2020

Added 2 new files:

07_Hairspring_Thin - Thinner hairspring to provide more headroom for frequency adjustment.

45_Tourbillon_Ring_Gear_Larger_OD: Received some feedback that ring gear is too loosely fitted to the Base. Modified with larger 0.8mm larger OD for a tighter fit, increased clearance between runner gear and ring gear for smoother meshing.

Update Sep 13, 2020

Added the Escapement mechanism explanation in the assembly guide.

Added a Stp file of the escape fork for those who want to optimize the performance further.

Added a "safe" escape fork design (03_Escape_Fork_Reduced) that should be able to cater to more significant variations in assembly, printer setup, print settings, etc. (I recommend those who had issues with the mechanism slipping and jamming to give this version a try)

Added high res assembly guide in the download zip.

Fixed some minor details in the runner gear and Tourbillon cage bottom files.

Fixed some qty errors in the assembly guide.

Update Sep 8, 2020

Added Display stand and winding key! Apologies for the long wait to those who requested. Do download the latest zip file dated (08Sept).

Mini Mechanica

Check my Youtube channel https://www.youtube.com/watch?v=PIIh2xiP-oM to grab Discount Code for the Grand Piano Crowdfunding.

Support my latest Project from 8th February 2022 with 72hrs Earlybird on the first 3 days.

Check the campaign here: https://mmf.io/mechgrandpianocfxobj

Product description of this object

The Mini Mechanica is a sample of the Tri-Axial Tourbillon Model. User should try this model out before attempting to build the full Tri-Axial:

If you are able to succesfully print and assemble a working model of the mini, the similar print settings and assembly approach will work for the Tri-Axial.

The Tourbillon Mechanica Tri-Axial is still available for Late Pledge via the link below

Late Pledge Here at discounted price!

Download the assembly guide here

estimated print time of Mini Mechanica is 7-12 hours, recommended on an FDM printer but resin would most likely work as well.

Mini Mechanica 2.0

Assembly Video: https://youtu.be/uwI5crQ6xUk

Micro Mechanica Video: https://youtu.be/V9r97uvhGfw

Free Assembly Guide (Bom list and printing details): Download

Important Note: Users who purchased the Tourbillon mechanica or backed the Tri-Axial campaign will be able to download this model for free.

Tourbillon Mechanica Buyers: Please check your Library > Objects Shared with me to download the file.

Tourbillon Mechanica Tri-Axial Backers: Please check your Library > Campaigns to download the file.

The runtime is only 4-8 minutes so take it as a fun little Mechanical wind up toy on your desk.

Files can also be found under Profile (Top right side of the page) -> Library -> Purchases -> Download the zip file

Pledge this tier at: https://mmf.io/mechgrandpianocfxobj This pledge includes: - Mini Mechanica (free) - Tourbillon Mechanica - Mini Mechanica 2.0 (WIP) Please note that the Mini Mechanica is also available as a free sample and does not count towards the total price of the pledge.

388 pioneers

USD 79.00

Tourbillon Mechanica Tri-Axial

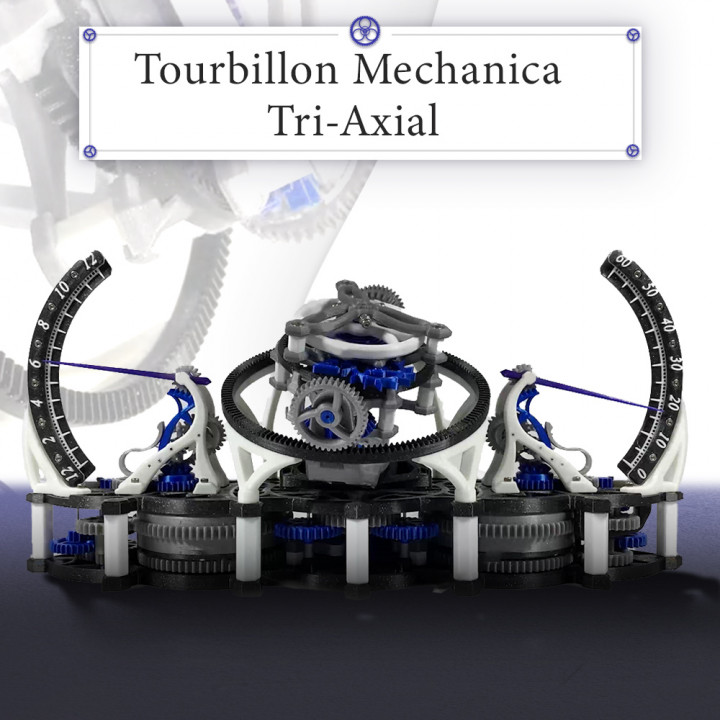

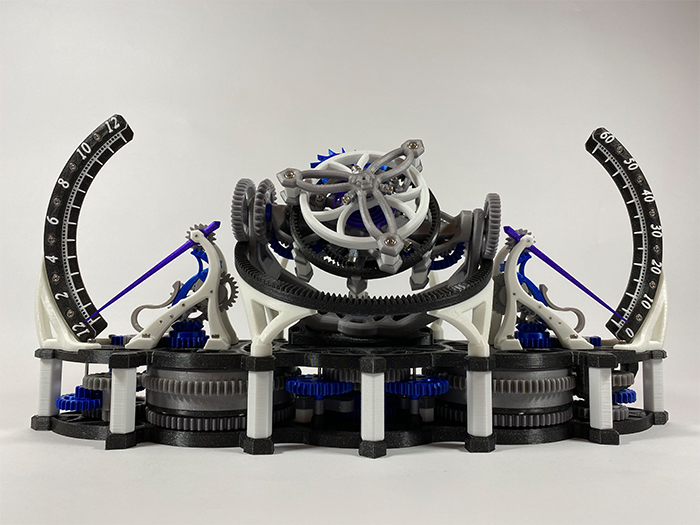

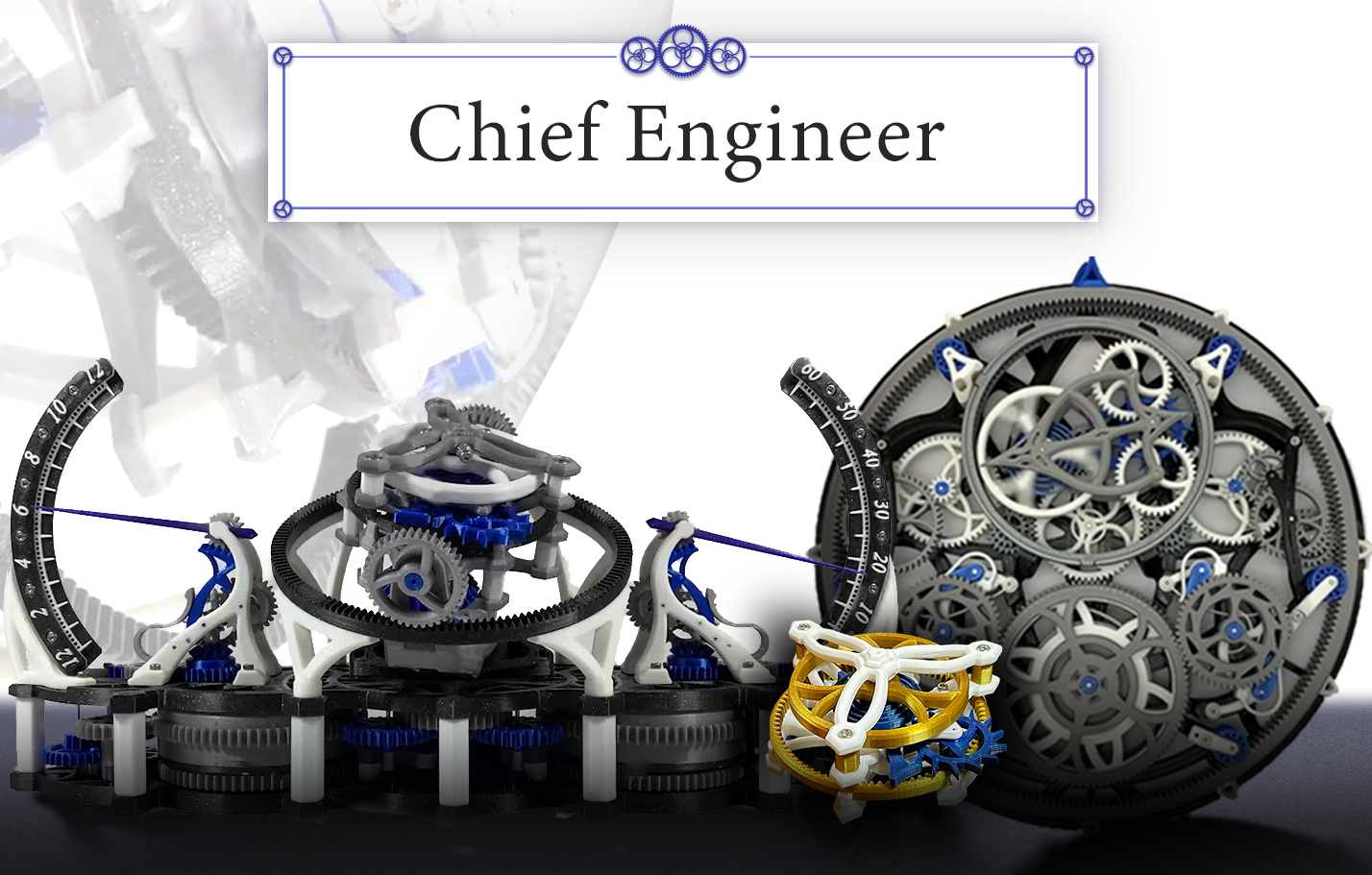

The Tourbillon Mechanica Tri-Axial clock is a step up in terms of complexity from the original Tourbillon Mechanica model. It is almost fully 3D printable (with the exception of metal pins and screws), and comes with a free 120+ page assembly guide.

Just like the Tourbillon Mechanica, although it is a functional mechanical clock, it is not a precise time-keeping machine and has limited runtime due to limitations of the 3D printed plastic material and accuracy.

The Tourbillon Tri-Axial clock has an Escapement Mechanism that rotates about 3 independent axes in order to cancel out the effects of gravity towards the frequency of the escapement mechanism.

It also includes two Retrograde Mechanisms; these are simplified 3D printed versions of a mechanism found in most high-end mechanical watches. Here the pointer only sweeps through a small angle, rather than the full 360º revolution, and then the pointer jumps back to its initial position after making a full angle sweep. In this model one measures the minutes, the other measures the hour.

Every single aspect of this mechanism has been carefully designed and considered across many months of hard work, meaning you receive a flawless end product.

Reveal video of the Tourbillon Mechanica Tri-Axial here.

19-Oct-2021 (Major Update!)

Model Updates:

- Added a High Torque modification option to double the mainspring-tourbivlon torque (More details can be found in assembly guide)

- 01_Bottom_Base_High_Torque

- 02_Upper_Base_High_Torque

- 07_Ratchet_Bridge_High_Torque

- 10_Power_Transmission_High_Torque

- 02_Upper_Base: Removed redundant material below Bevel gear to eliminate binding possibility

- 69_Axis_2_Upper_Frame: Added dimple features on idler end to minimise contact with bevel stud - optimised clearance to minimise shift

- 70_Axis_2_Lower_Frame: reduced material for further weight reduction to aid balancing.

- 75_Axis_3_Cage: Updated design to cater for part 81 modification

- 80_Axis_3_Bevel_Gear: Updated design to cater for Part 81 modification

- 81_Axis_3_Angled_Base: Reversed bearing insertion direction to eliminate bearing sagging due to gravity over time. Reduced Axis angular tolerance compensation from 0.4deg to 0.2deg.

- 84_Winding_Key: Separated key body from head to allow easy replacement in the event of breakage

- 85_Winding_Key_Head: New separated winding key head

Assembly Guide Update

- Page 21 : Updated part list table to reflect addition of winding key head

- Page 113: Added winding key assembly details

- Page 119-121 : Added High torque modification details and assembly guide

- Page 126-127 : Added optional final step to permanently lock critical Tourbillon links

- Page 133: Updated Cura screenshot of 81_Axis_3_Angled_Base to reflect additional required support

Mini Mechanica

Check my Youtube channel https://www.youtube.com/watch?v=PIIh2xiP-oM to grab Discount Code for the Grand Piano Crowdfunding.

Support my latest Project from 8th February 2022 with 72hrs Earlybird on the first 3 days.

Check the campaign here: https://mmf.io/mechgrandpianocfxobj

Product description of this object

The Mini Mechanica is a sample of the Tri-Axial Tourbillon Model. User should try this model out before attempting to build the full Tri-Axial:

If you are able to succesfully print and assemble a working model of the mini, the similar print settings and assembly approach will work for the Tri-Axial.

The Tourbillon Mechanica Tri-Axial is still available for Late Pledge via the link below

Late Pledge Here at discounted price!

Download the assembly guide here

estimated print time of Mini Mechanica is 7-12 hours, recommended on an FDM printer but resin would most likely work as well.

Mini Mechanica 2.0

Assembly Video: https://youtu.be/uwI5crQ6xUk

Micro Mechanica Video: https://youtu.be/V9r97uvhGfw

Free Assembly Guide (Bom list and printing details): Download

Important Note: Users who purchased the Tourbillon mechanica or backed the Tri-Axial campaign will be able to download this model for free.

Tourbillon Mechanica Buyers: Please check your Library > Objects Shared with me to download the file.

Tourbillon Mechanica Tri-Axial Backers: Please check your Library > Campaigns to download the file.

The runtime is only 4-8 minutes so take it as a fun little Mechanical wind up toy on your desk.

Files can also be found under Profile (Top right side of the page) -> Library -> Purchases -> Download the zip file

Pledge this tier at: https://mmf.io/mechgrandpianocfxobj This pledge includes: - Mini Mechanica (free) - Tourbillon Mechanica Tri-Axial - Mini Mechanica 2.0 (WIP) Please note that the Mini Mechanica is also available as a free sample and does not count towards the total price of the pledge.

1092 pioneers

USD 99.00

Tourbillon Mechanica Tri-Axial

The Tourbillon Mechanica Tri-Axial clock is a step up in terms of complexity from the original Tourbillon Mechanica model. It is almost fully 3D printable (with the exception of metal pins and screws), and comes with a free 120+ page assembly guide.

Just like the Tourbillon Mechanica, although it is a functional mechanical clock, it is not a precise time-keeping machine and has limited runtime due to limitations of the 3D printed plastic material and accuracy.

The Tourbillon Tri-Axial clock has an Escapement Mechanism that rotates about 3 independent axes in order to cancel out the effects of gravity towards the frequency of the escapement mechanism.

It also includes two Retrograde Mechanisms; these are simplified 3D printed versions of a mechanism found in most high-end mechanical watches. Here the pointer only sweeps through a small angle, rather than the full 360º revolution, and then the pointer jumps back to its initial position after making a full angle sweep. In this model one measures the minutes, the other measures the hour.

Every single aspect of this mechanism has been carefully designed and considered across many months of hard work, meaning you receive a flawless end product.

Reveal video of the Tourbillon Mechanica Tri-Axial here.

19-Oct-2021 (Major Update!)

Model Updates:

- Added a High Torque modification option to double the mainspring-tourbivlon torque (More details can be found in assembly guide)

- 01_Bottom_Base_High_Torque

- 02_Upper_Base_High_Torque

- 07_Ratchet_Bridge_High_Torque

- 10_Power_Transmission_High_Torque

- 02_Upper_Base: Removed redundant material below Bevel gear to eliminate binding possibility

- 69_Axis_2_Upper_Frame: Added dimple features on idler end to minimise contact with bevel stud - optimised clearance to minimise shift

- 70_Axis_2_Lower_Frame: reduced material for further weight reduction to aid balancing.

- 75_Axis_3_Cage: Updated design to cater for part 81 modification

- 80_Axis_3_Bevel_Gear: Updated design to cater for Part 81 modification

- 81_Axis_3_Angled_Base: Reversed bearing insertion direction to eliminate bearing sagging due to gravity over time. Reduced Axis angular tolerance compensation from 0.4deg to 0.2deg.

- 84_Winding_Key: Separated key body from head to allow easy replacement in the event of breakage

- 85_Winding_Key_Head: New separated winding key head

Assembly Guide Update

- Page 21 : Updated part list table to reflect addition of winding key head

- Page 113: Added winding key assembly details

- Page 119-121 : Added High torque modification details and assembly guide

- Page 126-127 : Added optional final step to permanently lock critical Tourbillon links

- Page 133: Updated Cura screenshot of 81_Axis_3_Angled_Base to reflect additional required support

Tourbillon Mechanica - Tourbillon Escapement Mechanical Clock (Assembly guide pdf in description)

Summer sale is here till end of August! Use the code MECHA40 for 40% off applicable to the entire store!

The Tourbillon Mechanica is an almost entirely 3D printed functional mechanical clock (except for metal pins and screws)

This skeletonized mechanical clock with a tourbillon escapement is designed to showcase a basic mechanical watch's mechanism. It has a unique hour and minute indicator that runs around the perimeter in order to showcase the entire mechanism.

Detailed assembly video guide: https://youtu.be/E9prY3ky6Bo

Detailed assembly guide, preparation and printing details: here

I received many requests on whether or not the Base (The largest single piece part) can be fitted onto some printers with slightly smaller rated build volume. There is a new split base and ring gear option that only requires a 160 x 110mm build area to print the entire model. The base and ring gear files can be downloaded for free as a fit check here.

Links to additional hardware that I used:

1.5mm OD Pins: Link

2.0mm OD Pins : Link

M2 Scews: Link

Sheet Spring Steel for mainspring : Link (Optional as I highly recommend using the 3D printed PETG spring)

Update Oct 09, 2021

Design Update:

- 10_Base_Split : Added split base option to reduce minimum printer bed size requirement significantly to 160 x 110mm

- 13_Ring_Gear_Split : Added split Ring gear option to reduce minimum printer bed size requirement

Assembly Guide Update:

- Page 3 : updated min print bed requirement from 220x220mm to 160x110mm

- Page 4-5 : added split base and ring gear assembly details

Update Dec 6, 2020

Added Step file of Base for those who wanted to try modifying it to fit smaller print beds. Step file can also be downloaded for free in the link above

Update Oct 27, 2020

Added 2 new files:

07_Hairspring_Thin - Thinner hairspring to provide more headroom for frequency adjustment.

45_Tourbillon_Ring_Gear_Larger_OD: Received some feedback that ring gear is too loosely fitted to the Base. Modified with larger 0.8mm larger OD for a tighter fit, increased clearance between runner gear and ring gear for smoother meshing.

Update Sep 13, 2020

Added the Escapement mechanism explanation in the assembly guide.

Added a Stp file of the escape fork for those who want to optimize the performance further.

Added a "safe" escape fork design (03_Escape_Fork_Reduced) that should be able to cater to more significant variations in assembly, printer setup, print settings, etc. (I recommend those who had issues with the mechanism slipping and jamming to give this version a try)

Added high res assembly guide in the download zip.

Fixed some minor details in the runner gear and Tourbillon cage bottom files.

Fixed some qty errors in the assembly guide.

Update Sep 8, 2020

Added Display stand and winding key! Apologies for the long wait to those who requested. Do download the latest zip file dated (08Sept).

Mini Mechanica

Check my Youtube channel https://www.youtube.com/watch?v=PIIh2xiP-oM to grab Discount Code for the Grand Piano Crowdfunding.

Support my latest Project from 8th February 2022 with 72hrs Earlybird on the first 3 days.

Check the campaign here: https://mmf.io/mechgrandpianocfxobj

Product description of this object

The Mini Mechanica is a sample of the Tri-Axial Tourbillon Model. User should try this model out before attempting to build the full Tri-Axial:

If you are able to succesfully print and assemble a working model of the mini, the similar print settings and assembly approach will work for the Tri-Axial.

The Tourbillon Mechanica Tri-Axial is still available for Late Pledge via the link below

Late Pledge Here at discounted price!

Download the assembly guide here

estimated print time of Mini Mechanica is 7-12 hours, recommended on an FDM printer but resin would most likely work as well.

Mini Mechanica 2.0

Assembly Video: https://youtu.be/uwI5crQ6xUk

Micro Mechanica Video: https://youtu.be/V9r97uvhGfw

Free Assembly Guide (Bom list and printing details): Download

Important Note: Users who purchased the Tourbillon mechanica or backed the Tri-Axial campaign will be able to download this model for free.

Tourbillon Mechanica Buyers: Please check your Library > Objects Shared with me to download the file.

Tourbillon Mechanica Tri-Axial Backers: Please check your Library > Campaigns to download the file.

The runtime is only 4-8 minutes so take it as a fun little Mechanical wind up toy on your desk.

Files can also be found under Profile (Top right side of the page) -> Library -> Purchases -> Download the zip file

Pledge this tier at: https://mmf.io/mechgrandpianocfxobj This pledge includes all of the mechanical STLs from the crowdfunding campaign: - Mini Mechanica (free) - Tourbillon Mechanica - Tourbillon Mechanica Tri-Axial - Mini Mechanica 2.0 (WIP) Please note that the Mini Mechanica is also available as a free sample and does not count towards the total price of the pledge.

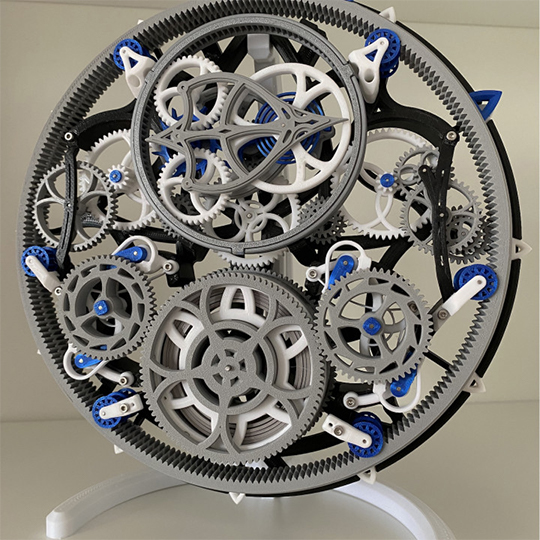

The Tourbillon Mechanica Tri-Axial is a step up in terms of complexity from the first Tourbillon Mechanica model, released in July 2020 on MyMiniFactory. It adopts a similar design approach in terms of maintaining symmetry and having a skeletonized frame in an attempt to showcase the working components as much as possible.

Just like the Tourbillon Mechanica, although it is a functional mechanical clock, it is not a precise time-keeping machine and has limited runtime due to limitations of the 3D printed plastic material and accuracy. Nonetheless, this is an innovative project to invest yourself into and an engineer’s dream.

The Tri-Axial was designed with the intention of being a functional mechanical sculpture that allows users to have a first-hand understanding and experience in the assembly and construction of the extremely expensive mechanism that can only be found in 6 figure price tag luxury mechanical watches.

Background

I'm not a watchmaker, but as a mechanical engineer who is both a watch nerd and 3D printing geek, I was greatly inspired by Christoph Laimer and Adam Wrigly's efforts (you can look them up on youtube) in creating a fully functional 3D printed clock and triple axis tourbillon respectively.

They made me realize that it is possible for consumer-level FDM 3D printers to produce such complex mechanisms as long as it is designed correctly. When I first laid my eyes on a triple-axis tourbillon watch, I was extremely mesmerized yet puzzled by the ingenuity of this mechanism that looks both complex and artistic at the same time. The triple-axis tourbillon is considered to be one of the pinnacles of watchmaking technical challenges and not only are they extremely rare, but they are also extremely expensive, most coming in the range of a $200,000 - 500,000 price tag.

Since its release 8 months ago, the original Tourbillon Mechanica has received much interest from the community both on MyMiniFactory and beyond. I was totally blown away by all the support and it was a pleasure to see others sharing in enjoyment and passion. Because of this, I have spent the last 6 months working hard to create this even more intricate design with you all and have no doubt that this will be a really fun project to invest yourself in.

This is my first time running a crowdfunding campaign and it made sense to me to share the campaign on MyMiniFactory, as this is where my previous designs have found such success.

The Design

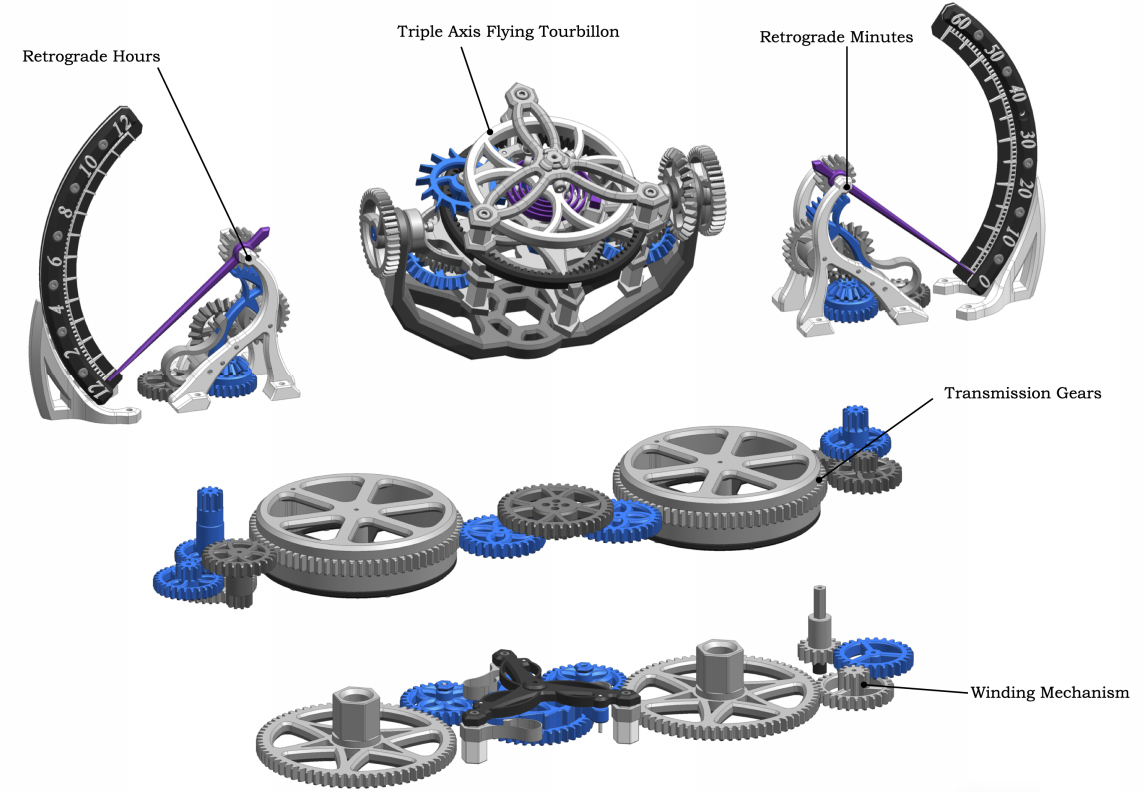

Triple Axis Tourbillon

The core of the design is the Triple Axis Tourbillon mechanism that sits in the middle of the assembly. For those who are new to mechanical watches and clocks, a Tourbillon is an assembly that rotates the escapement mechanism (the time regulation mechanism) about an axis in order to cancel out the effects of positional variation on the time regulation. A triple-axis tourbillon rotates the escapement mechanism about 3 independent axes.

Truth to be told, adding another layer to the mechanism helps bring the design even further to life. The tourbillon mechanism reduces the effect of gravity and external factors, which is one of the many elements that make the design such a premium, highly-sought-after product.

The assembly of the Tri-Axial is as much a project in itself as the printing of it. I have spent the past months iterating, optimizing and simplifying every single component of the mechanism in order to simplify the assembly and printing process. I designed the Tri-Axial with simplicity and accessibility in mind in the hope that it would appeal to more of you who are considering immersing yourselves in mechanical 3D printing.

It is designed to be printed with standard FDM 3D printers with common PLA and PETG materials.

The Triple Axis Tourbillon is not just a mechanical phenomenon, but a work of art, and sharing this innovative design with the 3D printing community on MyMiniFactory is a very exciting venture! Not just for me, but for the whole community.

Retrograde Mechanism

The hour + minute indicators both have jumping retrograde mechanisms, each sweeping through a 90-degree angle before jumping back to its initial position at the bottom. As mentioned earlier, symmetry is the approach for the design and it was quite a challenge to arrange and size the hour and minute transmission gears such that they are visually symmetrical as much as possible

Twin Mainspring Barrels

The two Mainspring barrels are the source of power that drives the entire mechanism. The retrograde mechanism and other functions are built around this core element.

For more details on the history of the Tourbillon and my story, have a read of this blog post by MyMiniFactory here.

To some of you, the Tourbillon Mechanica Tri-Axial may seem to be an intimidating project at first glance. To others, this may be the first time that you have considered taking on such a project. If, like me, you are fascinated by the intricacies of mechanical 3D printing and have a passion for design engineering, then I have no doubt that this pioneering campaign will be a great first step into the world.

I am also giving away a free ‘Mini Mechanica’ to those who may want to try out a simpler mechanism before pledging. It has an identical design to the 1st axis tourbillon on the Tri-axial and it should provide a higher level of confidence in terms of print settings and assembly procedures that can be applied to the larger assembly. You will also find attached a free assembly guide PDF, all you need to do is provide your email to MyMiniFactory and they will send you the file for free within 24 hours!

Since giving away the Mini Mechanica for free, the community have been printing and sharing over on MyMiniFactory’s new subreddit r/3DPrintCommunity! I am totally blown away with all of your stunning prints!

There will be three pledge tiers available in this campaign, depending on your requirements and desires.

The Mini Mechanica is available for free if you sign-up for updates and campaign discounts, but I also wanted to include this design included in all of the pledge tiers so that all of the files can be accessed in one place and to keep the process as clear for backers as possible.

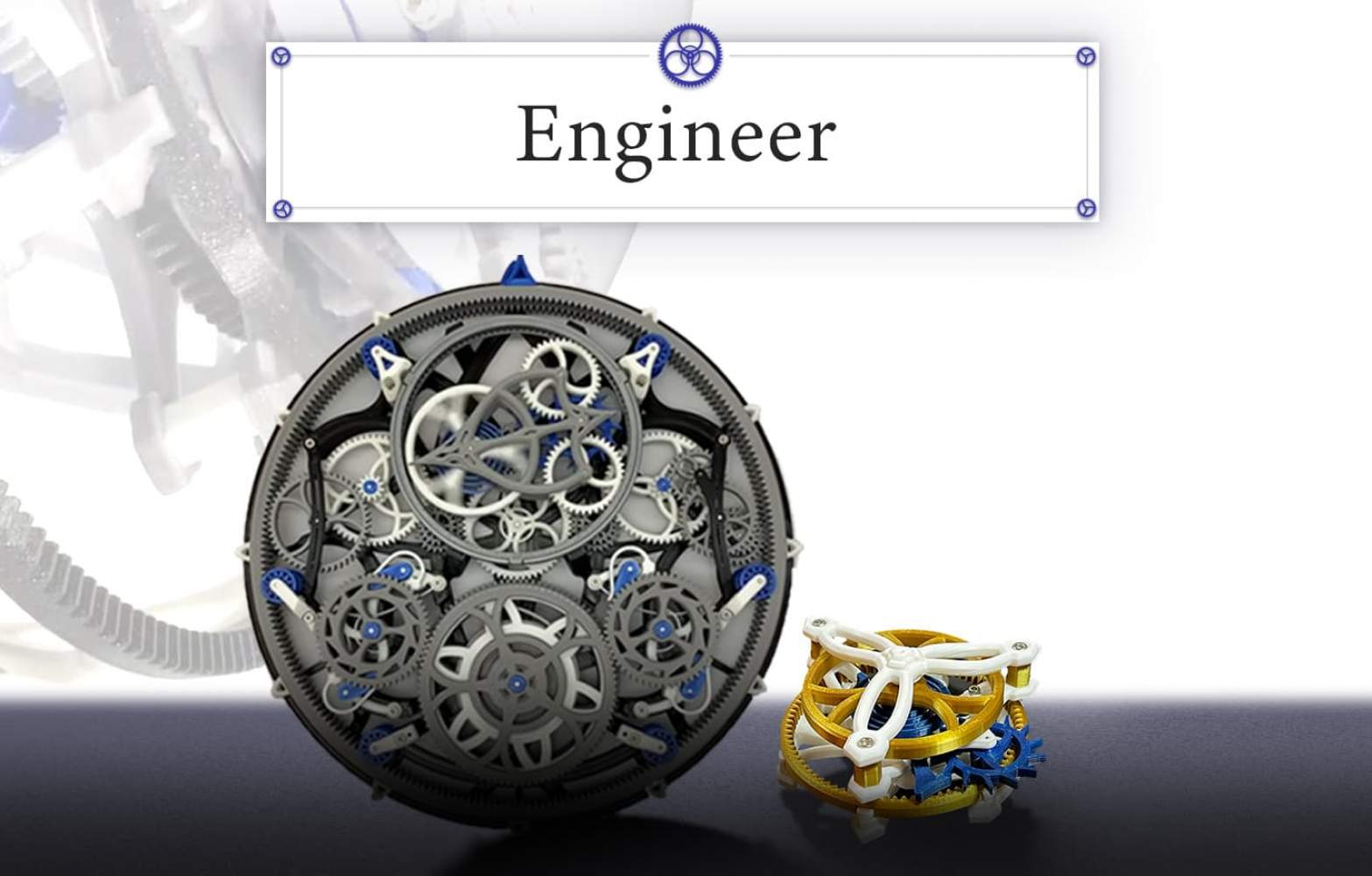

The first pledge tier, “Engineer” will consist of two mechanical designs: the Mini Mechanica (also available for free by signing up for updates) and the Tourbillon Mechanica. Does not include Tourbillon Tri-Axial.

ENGINEER

2 x Mechanical STLs

- Mini Mechanica

- Tourbillon Mechanica

The mid-tier pledge, “Lead Engineer”, will include two of the mechanical designs available through this campaign: the Mini Mechanica (also available for free by signing up for updates) and the Tourbillon Tri-Axial, the flagship mechanical design of the campaign. Does not include Tourbillon Mechanica.

LEAD ENGINEER

2 x Mechanical STLs

- Mini Mechanica

- Tourbillon Mechanica Tri-Axial

The third and final top tier pledge “Chief Engineer” includes all three of the mechanical designs available in the Tourbillon Tri-Axial Crowdfunding (Mini Mechanica, Tourbillon Mechanica & Tourbillon Mechanica Tri-Axial).

CHIEF ENGINEER

All Mechanical STLs

- Mini Mechanica

- Tourbillon Mechanica

- Tourbillon Mechanica Tri-Axial

I’ve compiled a step by step assembly and printing guide that also details some hardware requirements such as printer bed size, nozzle diameters and tools. The PDF guide can be downloaded for free below and I highly recommend vetting through the assembly steps in order to have a better idea of the assembly process.

Download PDF assembly guide

Upon the completion of the campaign, I will also release a detailed assembly video guide on my youtube channel to go along with the PDF guide.

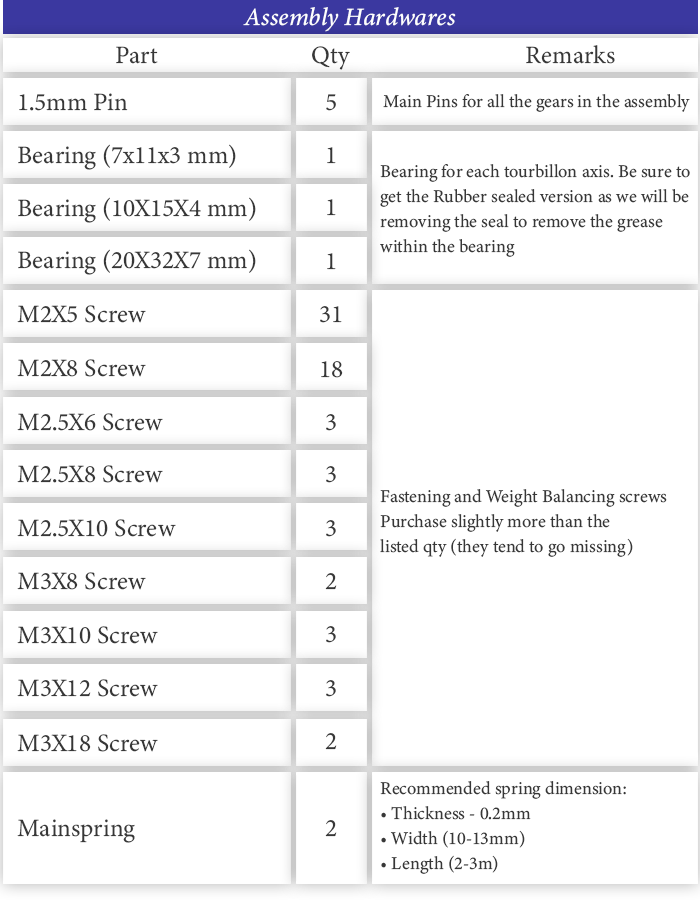

One very important thing to note is that the assembly is not 100% 3D printed. There are screws, pins, and 3 ball bearings (1 for each axis on the tourbillon), and mainspring (optional) that needs to be purchased separately and will not be included in the STL file package. The details and links to the non-printed components are provided in the assembly guide PDF.

A lot of these components can also be sourced in your local hardware stores; or alternatively through AliExpress, Amazon and other online marketplaces*. More detailed instructions can be found in the assembly guide PDF.

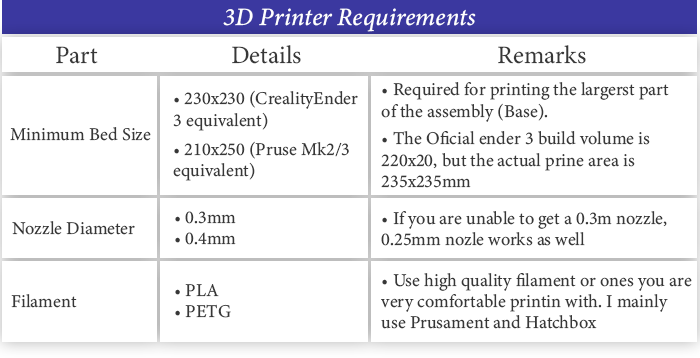

Printer and Hardware Requirements

Other Hardware

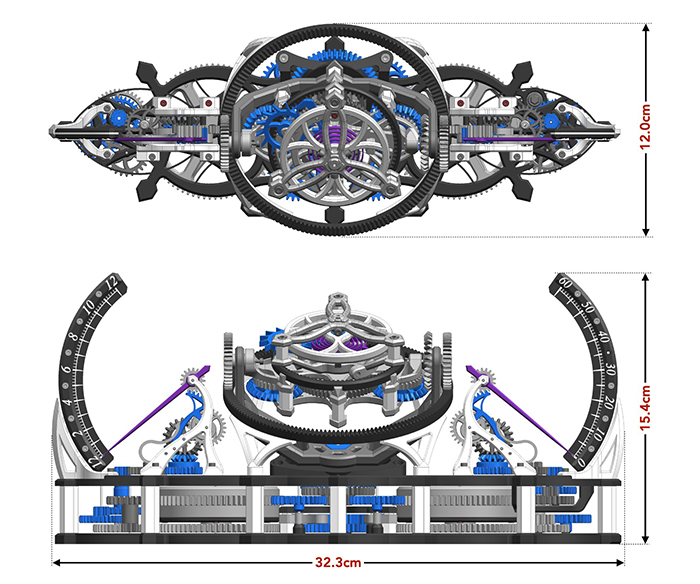

Design Specs

- Aproximate run time:

- PETG Spring - 10-15 minutes

- Steel Spring - 45-90 minutes

- Approximate material consumption: 700g PLA

- Approximate total print time: 140 hours

All further details can be found in the assembly guide PDF.

*Cost of assembly parts may vary (estimated $20-$60)

Risks & Challenges

From my experience with the first Tourbillon Mechanica, one of the major challenge in making such an intricate mechanism available for others is the fact that there will definitely be user to user variations due to the following factors:

1) Hardware variation - different printer models are calibrated in a different manner, slightly different nozzle diameters due to tolerances or wear and tear, printer x/y axis that is not sufficiently squared.

2) Filament Variation - Certain filaments have slightly higher shrinkage or vice versa, some cheaper filaments could have bad mechanical properties

3) Slicer setting Variation - Print temperatures, Print speeds.

I have taken measures to cater for these variations in this project and there will be iterative improvements moving forward as I receive feedback from those who encountered issues with the design or assembly.

File Release

This isn’t your typical crowdfunding campaign. That said, there will be no stretch goals to unlock since the Tourbillon Tri-Axial mechanism is enough of a project in itself.

Because the Tri-Axial design has been highly anticipated for such a long time now, I have been busy creating the mechanism so that the files will be ready for you all very soon. With this in mind, I have decided that the files will be released to all backers once the campaign is fully funded at $20,000.

Competition (Ended)

That’s not all! Once the crowdfunding campaign is funded, you will also unlock the Mechanical Maker Competition! Share your functional prints with the community on MyMiniFactory and r/3DPrintCommunity for a chance to win FDM printers from Anycubic and more top prizes.

See more on the Competition page here.

See the winners announcement here.

Where can I find the discount code?

If you are eligible for redeeming a discount code* (early sign-ups, sharing on Reddit or previous customers of Mechanistic), the discount code can be found in:

- Your MyMiniFactory Inbox

- MyMiniFactory Newsletter or email*

- Your Reddit inbox

*If you believe that you should have received a discount code, please check your junk email.

I have made a Pledge, when will I receive the files?

You will be able to receive the files when the funding goal is reached. If you pledged for the tier that contains Tourbillon Mechanica, you will receive the file immediately. Further updates regarding the release date will be announced by Mechanistic. You will be notified via email or an update when the files are available for download in your MyMiniFactory Inbox.

When will I be charged?

You will be charged immediately after a pledge has been made or an add-on has been purchased. You can review your order on the Order Details page.

Where can I review my pledge that I purchased?

You can review your pledge under the Pledge tab of the campaign. Your files can be found in your library (under 'campaigns') on MyMiniFactory or Order Details page.

What’s the minimum print bed size for printing Tri-Axial?

230mm x 230mm or 210mm X 250mm.

Mechanistic: “Required for printing the largest part of the assembly (Base). Please download the Base stl here and perform a fit check for your printer.

*Important Note: The Official Ender 3 build volume is 220 X 220 but the actual available print area is 235 x 235mm. Further information is available in the Assembly Guide here.”

What’s the recommended material of filament to use?

PLA or PETG.

Mechanistic: “You can use high quality filament or ones that you are very comfortable printing with. I mainly use Prusament and Hatchbox.”

What’s the recommended Nozzle Diameter?

0.3mm or 0.4mm

Mechanistic: “If you are unable to get a 0.3mm nozzle, a 0.25mm works as well.”

How much time does it take to print and assemble the Tourbillon Tri-Axial approximately?

It takes about 140 hours to print all the parts. 170 hours in total to print and assemble the Tourbillon Tri-Axial. There are some hardwares that are not 3D printable, which need to be purchased at local hardware shops, AliExpress or Amazon depending on where your location is. Further information is available in the Assembly Guide here.

How much do I need to spend to buy all the non-3D printable components approximately?

It varies depending on where you purchase those components. You will need to spend approximately $20-$60 for basic-level components required. You can upgrade your Mainspring to a metal spring which will cost you around $60 depending on location. Further information you can download the Assembly Guide here.

How long can a Tri-Axial run?

Approximate run time:

- PETG Spring - 10-15 minutes

- Steel Spring - 45-90 minutes

I have questions about the files, who can I reach out to?

If you are concerned about issues such as the printability of the design, you can download the Assembly Guide here for more information

If you have any further questions about the content in a pledge, please reach out to the creator of the campaign, or leave a comment in the Comments section.

I need assistance with my payment or other issues, what can I do?

Please Contact MyMiniFactory if you have any issues with payment.

Once we receive the ticket we will get back to you in 3-5 business days.

Thank you for supporting Mechanistic and the 3D Printing Community!

Please update your notification settings if you want to get notified when there is a new comment.